|

|

- I'm Online Chat Now

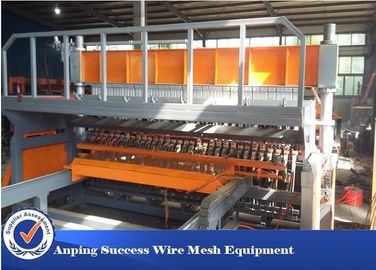

wire mesh manufacturing machine

Professional Wire Mesh Manufacturing Machine For Floor Roof Wire Netting 380v

Fence Mesh Welding Machine / Full Automatic / Wire Mesh Welding Machine

The automatic wire mesh welding machine is mainly used to weld fence and floor roof wire netting.

Operation processes: warps and wefts required by the equipment are pre-sheared by an automatic straightening cutting machine, the warps are placed on a corresponding warp groove, and the wefts are placed into a corresponding weft groove, and a fall feeder is controlled for automatic blanking and welding through a stepper motor respectively; the stepper motor controls a mesh drawing process to ensure accurate and uniform grids.

Both grid size and welding parameters are set by direct input on an operation panel, which is simple and accurate in operation..

Technical parameters:

| Wire diameter | 3-6mm | Rated voltage | 380V |

| Welding aperture | 50*50-300*300mm | Rated power | 750kva |

| Welding width | 2500mm | Dimensions | 6x3.2x1.8m |

| Warp quantity | 48 | Machine weight | 4.2t |

| Welding speed | 60 times/min | welding mesh length | 6-12m |

Pneumatic Reinforcing Wire Mesh Manufacturing Machine Easy Operation Width 2500mm

Pneumatic Reinforcing Wire Mesh Making Machine Width 2500mm

The working process

1. Feeding: Cross wire & Line wire are both pre-cut wires. Cross wires are feeded to the mould manually then the wire falling autoamticlly, while line wires are automatically feeded by the servo motor.

2.Welding: The main machine starts welding and adopts a synchronous control technology, both branch control welding time and welding time are controlled by a PLC digital programming system, and the pore size can be adjusted only by direct input on a touch screen control panel; welding power is pneumatic, and welding pressure can be easily and intuitively adjusted.

3.Welding finish: The servo motor controls an automatic mesh drawing process until the whole mesh is welded, and the automatic mesh connecting and discharging system is started; the welding of the next mesh is started.

The machine is introduced

Pneumatic steel mesh welding machine type used in the manufacture of pre-straightened and cut,simple and compact welding production line for a mass production of small and medium-sized steel mesh,can be welded ,and other welded mesh fence. Native multi-stage electric resistance welding principle,the vertical bars,horizontal bars according to the set requirements,welded into a solid mesh.Suitable can be cold -rolled steel ribbed steel,hot -rolled or cold -rolled smooth steel bars.

Accessories

1. air tank

2. air compressor

3. wire straighting and cutting machine

4. bobbin

Technical parameters

| Model: | JG-05 | Net Width: | 2500mm |

|---|---|---|---|

| Working Speed: | 60 | Rated Power: | 2000KVA |

| Host Size: | 4*3.4*2.6m | Weight: | 8t |

| Wire diameter | 5mm-12mm | Warp feeding | Pre-cut |

| Weft distance | Min. 50mm | Weft feeding | Pre-cut |

| Warp distance | 100mm-300mm | Power supply | AC380V-440V |

| Warp quantity | 26 | Welding width | 2500mm |

| Mesh length | 12m | Welding speed | 45 times/min |

| Dimensions | 10*3.4*1.8(m) | Welding capacity | 12mm+12mm |

High Speed Wire Mesh Manufacturing Machine Adopts Synchronous Control Technique

Fence Machine / Welding Fence / Wire Mesh Making Machine

The machine introduced

The machine adopts synchronous control technique,both welding time aned separate welding are digital PLC programming system,of which the input panel for the touch screen,the operation more intellingent ,rationaliza-tion,and has a compression, sub-sub -welding characteristics.The biggest advantage of the machine is:size between the weft and woof of a hole may appear in the same medium.

Mechanical uses

Fence (road,rail)fence ,with a net floor pouring top.

The machine parameter

| Welding wire diameter | 3mm-6mm | Rated voltage | 380V |

| Welding aperture | 50*50-300*300mm | Rated voltage | 750KVA |

| Welding width | 2500mm | Dimensions | 6*3.2*1.8m |

| The number of warp | 48 | Machine weight | 4.2t |

| Welding speed(beats/min) | 60 |

Animal Wire Cage Welding Machine , Wire Mesh Manufacturing Machine 380V - 420V

Animal Cage Wire Mesh Welding Machine / Rated Voltage 380V-420V / Wire Diameter 1.8-3.2mm

Feeding mode

Wefts are cut off in a straightening mode, warps are coil wires.

The weft blanking mechanism takes materials from a hopper and is uniform and accurate in blanking, meshes do not need welding in a trimmed mode due to tidy edges (full-automatic welding); a power electronic synchronous control technology is adopted, both welding time and branch control welding are formed by a digital integrated circuit, the control accuracy is high, welding sports are firm, and burn marks cannot be formed.

Meshes are drawn by an elastic pull rod and a grid positioning device, so that grids are easy to adjust slightly and high in dimensional accuracy, and the apertures of welded meshes can be adjusted at random in a certain range.

Application

cultivation meshes and poultry meshes

Technical parameters

| Wire diameter | 1.8-3.2mm | Rated voltage | 380V-420V(customized) |

| Welding aperture | 25*25-200*200mm | Rated power | Customized |

| Welding width | 1200mm | Dimensions | 1.8x2.5x1.8m |

| Warp quantity | 25 | Machine weight | 3.2t |

| Welding speed | 80times/min | Welding length | Customized |

The above parameters can be customized according to customer requirements.

Accessories

1. wire straightening and cutting machine

2. bobbin

Automatic Wire Mesh Manufacturing Machine High Speed 50X50-200X200MM

Automatic Welded Mesh Machine / Wire Mesh Machine / Automatic Straight Weft

Specifications

Automatic Welded Mesh Machine JG

1. width:1200mm-3000mm

2. wire diameter:1.4mm-2.5mm

3. mesh:50*50-200*200mm

Automatic Welded Mesh Machine JG

Peculiarity: Box-style support, high stability, lower noise, E-Machine in one, straighten & send wire automatically. Used for welded wire mesh 1.4-2.5mm

| Welding wire diameter | 1.4-2.5mm | Rated voltage | 380V, 420V (customizable) |

| Welding aperture | 50X50-200X200MM | Rated power | Customized |

| Welding width | 1200mm | Dimensions | 1.8x2.5x1.8m |

| Warp quantity | 25 | Machine weight | 3.2t |

| Welding speed | 80times/min |

Tel: 86--18631814662

Fax: 86-318-7599992